Propeller

A propeller is a type of fan that transmits power by converting rotational motion into thrust. A pressure difference is produced between the forward and rear surfaces of the airfoil-shaped blade, and a fluid (such as air or water) is accelerated behind the blade. Propeller dynamics can be modeled by both Bernoulli's principle and Newton's third law. A propeller is often colloquially known as screw both in aviation and maritime.

Contents

|

History

The principle employed in using a screw propeller is used in sculling. It is part of the skill of propelling a Venetian gondola but was used in a less refined way in other parts of Europe and probably elsewhere. For example, propelling a canoe with a single paddle using a "j-stroke" involves a related but not identical technique. In China, sculling, called "lu", was also used by the 3rd century AD.

In sculling, a single blade is moved through an arc, from side to side taking care to keep presenting the blade to the water at the effective angle. The innovation introduced with the screw propeller was the extension of that arc through more than 360° by attaching the blade to a rotating shaft. Propellers can have a single blade, but in practice there are nearly always more than one so as to balance the forces involved.

The origin of the screw propeller starts with Archimedes, who used a screw to lift water for irrigation and bailing boats, so famously that it became known as Archimedes' screw. It was probably an application of spiral movement in space (spirals were a special study of Archimedes) to a hollow segmented water-wheel used for irrigation by Egyptians for centuries. Leonardo da Vinci adopted the principle to drive his theoretical helicopter, sketches of which involved a large canvas screw overhead.

In 1784, J. P. Paucton proposed a gyrocopter-like aircraft using similar screws for both lift and propulsion. At about the same time, James Watt proposed using screws to propel boats, although he did not use them for his steam engines. This was not his own invention, though; Toogood and Hays had patented it a century earlier, and it had become a common use as a means of propelling boats since that time.

By 1827, Czech-Austrian inventor Josef Ressel had invented a screw propeller which had multiple blades fastened around a conical base. He had tested his propeller in February 1826 on a small ship that was manually driven. He was successful in using his bronze screw propeller on an adapted steamboat (1829). His ship "Civette" (48 BRT) reached a speed of about six knots (11 km/h. This was the first ship successfully driven by a propeller. After a new steam engine had an accident (cracked pipe weld) his experiments where banned by the Austro-Hungarian police as dangerous. Josef Ressel was at the time an officer of Austro-Hungarian Navy. But before this he received a Austro-Hungarian patent (license) for his propeller (1827). He died in 1857 and in 1866 the US academy confirmed his license for a ship propeller. This new method of propulsion allowed steam ships to travel at a much greater speed without using sails thereby making ocean travel faster.

John Patch, a mariner in Yarmouth, Nova Scotia developed a two-bladed, fan-shaped propeller in 1832 and publicly demonstrated it in 1833, propelling a row boat across Yarmouth Harbour and a small coastal schooner at Saint John, New Brunswick, but his patent application in the United States was rejected until 1849 because he was not an American citizen.[1] His efficient design drew praise in American scientific circles[2] but by this time there were multiple competing versions of the marine propeller.

In 1835 Francis Pettit Smith discovered a new way of building propellers. Up to that time, propellers were literally screws, of considerable length. But during the testing of a boat propelled by one, the screw snapped off, leaving a fragment shaped much like a modern boat propeller. The boat moved faster with the broken propeller.[3] At about the same time, Frédéric Sauvage and John Ericsson applied for patents on vaguely similar, although less efficient shortened-screw propellers, leading to an apparently permanent controversy as to who the official inventor is among those three men. Ericsson became widely famous when he built the Monitor, an armoured battleship that in 1862 fought the Confederate States’ Virginia in an American Civil War sea battle.

The superiority of screw against paddles was taken up by navies. Trials with Smith's SS Archimedes, the first steam driven screw, led to the famous tug-of-war competition in 1845 between the screw-driven HMS Rattler and the paddle steamer HMS Alecto; the former pulling the latter backward at 2.5 knots (4.6 km/h).

In the second half of the nineteenth century, several theories were developed. The momentum theory or disk actuator theory—a theory describing a mathematical model of an ideal propeller—was developed by W.J.M. Rankine (1865), Alfred George Greenhill (1888) and R.E. Froude (1889). The propeller is modeled as an infinitely thin disc, inducing a constant velocity along the axis of rotation. This disc creates a flow around the propeller. Under certain mathematical premises of the fluid, there can be extracted a mathematical connection between power, radius of the propeller, torque and induced velocity. Friction is not included.

The blade element theory (BET) is a mathematical process originally designed by William Froude (1878), David W. Taylor (1893) and Stefan Drzewiecki to determine the behavior of propellers. It involves breaking an airfoil down into several small parts then determining the forces on them. These forces are then converted into accelerations, which can be integrated into velocities and positions.

The twisted airfoil (aerofoil) shape of modern aircraft propellers was pioneered by the Wright brothers. While both the blade element theory and the momentum theory had their supporters, the Wright brothers were able to combine both theories. They found that a propeller is essentially the same as a wing and so were able to use data collated from their earlier wind tunnel experiments on wings. They also found that the relative angle of attack from the forward movement of the aircraft was different for all points along the length of the blade, thus it was necessary to introduce a twist along its length. Their original propeller blades are only about 5% less efficient than the modern equivalent, some 100 years later.[4]

Alberto Santos Dumont was another early pioneer, having designed propellers before the Wright Brothers (albeit not as efficient) for his airships. He applied the knowledge he gained from experiences with airships to make a propeller with a steel shaft and aluminium blades for his 14 bis biplane. Some of his designs used a bent aluminium sheet for blades, thus creating an airfoil shape. These are heavily undercambered because of this and combined with the lack of a lengthwise twist made them less efficient than the Wright propellers. Even so, this was perhaps the first use of aluminium in the construction of an airscrew.

Aviation

Aircraft propellers convert rotary motion from piston engines or turboprops to provide propulsive force. They may be fixed or variable pitch. Early aircraft propellers were carved by hand from solid or laminated wood with later propellers being constructed from metal. The most modern propeller designs use high-technology composite materials.

As well as being used for fixed wing aircraft, these propellers are also used for helicopters, and other vehicles such as hovercraft, airboats and some trains (such as the Schienenzeppelin).

Marine

|

1) Trailing edge |

6) Leading edge |

A propeller is the most common propulsor on ships, imparting momentum to a fluid which causes a force to act on the ship.

The ideal efficiency of any size propeller (free-tip) is that of an actuator disc in an ideal fluid. An actual marine propeller is made up of sections of helicoidal surfaces which act together 'screwing' through the water (hence the common reference to marine propellers as "screws"). Three, four, or five blades are most common in marine propellers, although designs which are intended to operate at reduced noise will have more blades. The blades are attached to a boss (hub), which should be as small as the needs of strength allow - with fixed pitch propellers the blades and boss are usually a single casting.

An alternative design is the controllable pitch propeller (CPP, or CRP for controllable-reversible pitch), where the blades are rotated normally to the drive shaft by additional machinery - usually hydraulics - at the hub and control linkages running down the shaft. This allows the drive machinery to operate at a constant speed while the propeller loading is changed to match operating conditions. It also eliminates the need for a reversing gear and allows for more rapid change to thrust, as the revolutions are constant. This type of propeller is most common on ships such as tugs where there can be enormous differences in propeller loading when towing compared to running free, a change which could cause conventional propellers to lock up as insufficient torque is generated. The downsides of a CPP/CRP include: the large hub which decreases the torque required to cause cavitation, the mechanical complexity which limits transmission power and the extra blade shaping requirements forced upon the propeller designer.

For smaller motors there are self-pitching propellers. The blades freely move through an entire circle on an axis at right angles to the shaft. This allows hydrodynamic and centrifugal forces to 'set' the angle the blades reach and so the pitch of the propeller.

A propeller that turns clockwise to produce forward thrust, when viewed from aft, is called right-handed. One that turns anticlockwise is said to be left-handed. Larger vessels often have twin screws to reduce heeling torque, counter-rotating propellers, the starboard screw is usually right-handed and the port left-handed, this is called outward turning. The opposite case is called inward turning. Another possibility is contra-rotating propellers, where two propellers rotate in opposing directions on a single shaft, or on separate shafts on nearly the same axis. One example of the latter is the CRP Azipod by the ABB Group. Contra-rotating propellers offer increased efficiency by capturing the energy lost in the tangential velocities imparted to the fluid by the forward propeller (known as "propeller swirl"). The flow field behind the aft propeller of a contra-rotating set has very little "swirl", and this reduction in energy loss is seen as an increased efficiency of the aft propeller.

Additional designs

An azimuthing propeller is a vertical axis propeller.

The blade outline is defined either by a projection on a plane normal to the propeller shaft (projected outline) or by setting the circumferential chord across the blade at a given radius against radius (developed outline). The outline is usually symmetrical about a given radial line termed the median. If the median is curved back relative to the direction of rotation the propeller is said to have skew back. The skew is expressed in terms of circumferential displacement at the blade tips. If the blade face in profile is not normal to the axis it is termed raked, expressed as a percentage of total diameter.

Each blade's pitch and thickness varies with radius, early blades had a flat face and an arced back (sometimes called a circular back as the arc was part of a circle), modern propeller blades have aerofoil sections. The camber line is the line through the mid-thickness of a single blade. The camber is the maximum difference between the camber line and the chord joining the trailing and leading edges. The camber is expressed as a percentage of the chord.

The radius of maximum thickness is usually forward of the mid-chord point with the blades thinning to a minimum at the tips. The thickness is set by the demands of strength and the ratio of thickness to total diameter is called blade thickness fraction.

The ratio of pitch to diameter is called pitch ratio. Due to the complexities of modern propellers a nominal pitch is given, usually a radius of 70% of the total is used.

Blade area is given as a ratio of the total area of the propeller disc, either as developed blade area ratio or projected blade area ratio.

Transverse axis propellers

Most propellers have their axis of rotation parallel to the fluid flow. There have however been some attempts to power vehicles with the same principles behind vertical axis wind turbines, where the rotation is perpendicular to fluid flow. Most attempts have been unsuccessful. Blades that can vary their angle of attack during rotation have aerodynamics similar to flapping flight. Flapping flight is still poorly understood and almost never seriously used in engineering because of the strong coupling of lift, thrust and control forces.

The fanwing is one of the few types that has actually flown. It takes advantage of the trailing edge of an airfoil to help encourage the circulation necessary for lift.

The Voith-Schneider propeller pictured below is another successful example, operating in water.

History of ship and submarine screw propellers

James Watt of Scotland is generally credited with applying the first screw propeller to an engine at his Birmingham works, an early steam engine, beginning the use of an hydrodynamic screw for propulsion.

Mechanical ship propulsion began with the steam ship. The first successful ship of this type is a matter of debate; candidate inventors of the 18th century include William Symington, the Marquis de Jouffroy, John Fitch and Robert Fulton, however William Symington's ship the Charlotte Dundas is regarded as the world's "first practical steamboat". Paddlewheels as the main motive source became standard on these early vessels (see Paddle steamer). Robert Fulton had tested, and rejected, the screw propeller.

The screw (as opposed to paddlewheels) was introduced in the latter half of the 18th century. David Bushnell's invention of the submarine (Turtle) in 1775 used hand-powered screws for vertical and horizontal propulsion. The Bohemian engineer Josef Ressel designed and patented the first practicable screw propeller in 1827. Francis Pettit Smith tested a similar one in 1836. In 1839, John Ericsson introduced practical screw propulsion into the United States. Mixed paddle and propeller designs were still being used at this time (vide the 1858 Great Eastern).

The screw propeller replaced the paddles owing to its greater efficiency, compactness, less complex power transmission system, and reduced susceptibility to damage (especially in battle)

Initial designs owed much to the ordinary screw from which their name derived - early propellers consisted of only two blades and matched in profile the length of a single screw rotation. This design was common, but inventors endlessly experimented with different profiles and greater numbers of blades. The propeller screw design stabilized by the 1880s.

In the early days of steam power for ships, when both paddle wheels and screws were in use, ships were often characterized by their type of propellers, leading to terms like screw steamer or screw sloop.

Propellers are referred to as "lift" devices, while paddles are "drag" devices.

Marine propeller cavitation

Cavitation can occur if an attempt is made to transmit too much power through the screw, or if the propeller is operating at a very high speed. Cavitation can occur in many ways on a propeller. The two most common types of propeller cavitation are suction side surface cavitation and tip vortex cavitation.

Suction side surface cavitation forms when the propeller is operating at high rotational speeds or under heavy load (high blade lift coefficient). The pressure on the upstream surface of the blade (the "suction side") can drop below the vapor pressure of the water, resulting in the formation of a pocket of vapor. Under such conditions, the change in pressure between the downstream surface of the blade (the "pressure side") and the suction side is limited, and eventually reduced as the extent of cavitation is increased. When most of the blade surface is covered by cavitation, the pressure difference between the pressure side and suction side of the blade drops considerably, as does the thrust produced by the propeller. This condition is called "thrust breakdown". Operating the propeller under these conditions wastes energy, generates considerable noise, and as the vapor bubbles collapse it rapidly erodes the screw's surface due to localized shock waves against the blade surface.

Tip vortex cavitation is caused by the extremely low pressures formed at the core of the tip vortex. The tip vortex is caused by fluid wrapping around the tip of the propeller; from the pressure side to the suction side. This video demonstrates tip vortex cavitation well. Tip vortex cavitation typically occurs before suction side surface cavitation and is less damaging to the blade, since this type of cavitation doesn't collapse on the blade, but some distance downstream.

Cavitation can be used as an advantage in design of very high performance propellers, in form of the supercavitating propeller. In this case, the blade section is designed such that the pressure side stays wetted while the suction side is completely covered by cavitation vapor. Because the suction side is covered with vapor instead of water it encounters very low viscous friction, making the supercavitating (SC) propeller comparably efficient at high speed. The shaping of SC blade sections however, make it inefficient at low speeds, when the suction side of the blade is wetted. (See also fluid dynamics).

A similar, but quite separate issue, is ventilation, which occurs when a propeller operating near the surface draws air into the blades, causing a similar loss of power and shaft vibration, but without the related potential blade surface damage caused by cavitation. Both effects can be mitigated by increasing the submerged depth of the propeller: cavitation is reduced because the hydrostatic pressure increases the margin to the vapor pressure, and ventilation because it is further from surface waves and other air pockets that might be drawn into the slipstream.

Forces acting on a foil

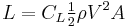

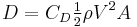

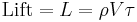

The force (F) experienced by a foil is determined by its area (A), fluid density (ρ), velocity (V) and the angle of the foil to the fluid flow, called angle of attack ( ), where:

), where:

The force has two parts - that normal to the direction of flow is lift (L) and that in the direction of flow is drag (D). Both can be expressed mathematically:

and

and

where CL and CD are lift coefficient and drag coefficient respectively.

Each coefficient is a function of the angle of attack and Reynolds' number. As the angle of attack increases lift rises rapidly from the no lift angle before slowing its increase and then decreasing, with a sharp drop as the stall angle is reached and flow is disrupted. Drag rises slowly at first and as the rate of increase in lift falls and the angle of attack increases drag increases more sharply.

For a given strength of circulation ( ),

),  . The effect of the flow over and the circulation around the aerofoil is to reduce the velocity over the face and increase it over the back of the blade. If the reduction in pressure is too much in relation to the ambient pressure of the fluid, cavitation occurs, bubbles form in the low pressure area and are moved towards the blade's trailing edge where they collapse as the pressure increases, this reduces propeller efficiency and increases noise. The forces generated by the bubble collapse can cause permanent damage to the surfaces of the blade.

. The effect of the flow over and the circulation around the aerofoil is to reduce the velocity over the face and increase it over the back of the blade. If the reduction in pressure is too much in relation to the ambient pressure of the fluid, cavitation occurs, bubbles form in the low pressure area and are moved towards the blade's trailing edge where they collapse as the pressure increases, this reduces propeller efficiency and increases noise. The forces generated by the bubble collapse can cause permanent damage to the surfaces of the blade.

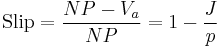

Propeller thrust

Single blade

Taking an arbitrary radial section of a blade at r, if revolutions are N then the rotational velocity is  . If the blade was a complete screw it would advance through a solid at the rate of NP, where P is the pitch of the blade. In water the advance speed is rather lower,

. If the blade was a complete screw it would advance through a solid at the rate of NP, where P is the pitch of the blade. In water the advance speed is rather lower,  , the difference, or slip ratio, is:

, the difference, or slip ratio, is:

where  is the advance coefficient, and

is the advance coefficient, and  is the pitch ratio.

is the pitch ratio.

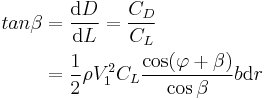

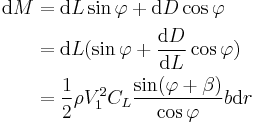

The forces of lift and drag on the blade, dA, where force normal to the surface is dL:

where:

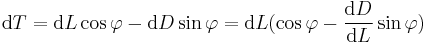

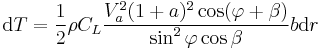

These forces contribute to thrust, T, on the blade:

where:

As  ,

,

From this total thrust can be obtained by integrating this expression along the blade. The transverse force is found in a similar manner:

Substituting for  and multiplying by r, gives torque as:

and multiplying by r, gives torque as:

which can be integrated as before.

The total thrust power of the propeller is proportional to  and the shaft power to

and the shaft power to  . So efficiency is

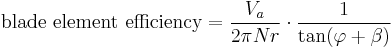

. So efficiency is  . The blade efficiency is in the ratio between thrust and torque:

. The blade efficiency is in the ratio between thrust and torque:

showing that the blade efficiency is determined by its momentum and its qualities in the form of angles  and

and  , where

, where  is the ratio of the drag and lift coefficients.

is the ratio of the drag and lift coefficients.

This analysis is simplified and ignores a number of significant factors including interference between the blades and the influence of tip vortices.

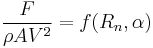

Thrust and torque

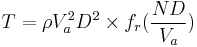

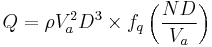

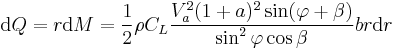

The thrust, T, and torque, Q, depend on the propeller's diameter, D, revolutions, N, and rate of advance,  , together with the character of the fluid in which the propeller is operating and gravity. These factors create the following non-dimensional relationship:

, together with the character of the fluid in which the propeller is operating and gravity. These factors create the following non-dimensional relationship:

where  is a function of the advance coefficient,

is a function of the advance coefficient,  is a function of the Reynolds' number, and

is a function of the Reynolds' number, and  is a function of the Froude number. Both

is a function of the Froude number. Both  and

and  are likely to be small in comparison to

are likely to be small in comparison to  under normal operating conditions, so the expression can be reduced to:

under normal operating conditions, so the expression can be reduced to:

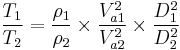

For two identical propellers the expression for both will be the same. So with the propellers  , and using the same subscripts to indicate each propeller:

, and using the same subscripts to indicate each propeller:

For both Froude number and advance coefficient:

where  is the ratio of the linear dimensions.

is the ratio of the linear dimensions.

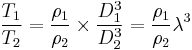

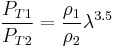

Thrust and velocity, at the same Froude number, give thrust power:

For torque:

Actual performance

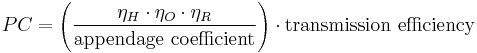

When a propeller is added to a ship its performance is altered; there is the mechanical losses in the transmission of power; a general increase in total resistance; and the hull also impedes and renders non-uniform the flow through the propeller. The ratio between a propeller's efficiency attached to a ship ( ) and in open water (

) and in open water ( ) is termed relative rotative efficiency.

) is termed relative rotative efficiency.

The overall propulsive efficiency (an extension of effective power ( )) is developed from the propulsive coefficient (

)) is developed from the propulsive coefficient ( ), which is derived from the installed shaft power (

), which is derived from the installed shaft power ( ) modified by the effective power for the hull with appendages (

) modified by the effective power for the hull with appendages ( ), the propeller's thrust power (

), the propeller's thrust power ( ), and the relative rotative efficiency.

), and the relative rotative efficiency.

/

/ = hull efficiency =

= hull efficiency =

/

/ = propeller efficiency =

= propeller efficiency =

/

/ = relative rotative efficiency =

= relative rotative efficiency =

/

/ = shaft transmission efficiency

= shaft transmission efficiency

Producing the following:

The terms contained within the brackets are commonly grouped as the quasi-propulsive coefficient ( ,

,  ). The

). The  is produced from small-scale experiments and is modified with a load factor for full size ships.

is produced from small-scale experiments and is modified with a load factor for full size ships.

Wake is the interaction between the ship and the water with its own velocity relative to the ship. The wake has three parts: the velocity of the water around the hull; the boundary layer between the water dragged by the hull and the surrounding flow; and the waves created by the movement of the ship. The first two parts will reduce the velocity of water into the propeller, the third will either increase or decrease the velocity depending on whether the waves create a crest or trough at the propeller.

Types of marine propellers

Controllable pitch propeller

One type of marine propeller is the controllable pitch propeller. This propeller has several advantages with ships. These advantages include: the least drag depending on the speed used, the ability to move the sea vessel backwards, and the ability to use the "vane"-stance, which gives the least water resistance when not using the propeller (e.g. when the sails are used instead).

Skewback propeller

An advanced type of propeller used on German Type 212 submarines is called a skewback propeller. As in the scimitar blades used on some aircraft, the blade tips of a skewback propeller are swept back against the direction of rotation. In addition, the blades are tilted rearward along the longitudinal axis, giving the propeller an overall cup-shaped appearance. This design preserves thrust efficiency while reducing cavitation, and thus makes for a quiet, stealthy design.[5]

Modular propeller

A modular propeller provides more control over the boats performance. There is no need to change an entire prop, when there is an opportunity to only change the pitch or the damaged blades. Being able to adjust pitch will allow for boaters to have better performance while in different altitudes, water sports, and/or cruising.[6]

Protection of small engines

For smaller engines, such as outboards, where the propeller is exposed to the risk of collision with heavy objects, the propeller often includes a device which is designed to fail when over loaded; the device or the whole propeller is sacrificed so that the more expensive transmission and engine are not damaged.

Typically in smaller (less than 10 hp/7.5 kW) and older engines, a narrow shear pin through the drive shaft and propeller hub transmits the power of the engine at normal loads. The pin is designed to shear when the propeller is put under a load that could damage the engine. After the pin is sheared the engine is unable to provide propulsive power to the boat until an undamaged shear pin is fitted.[7] Note that some shear pins used to have shear grooves machined into them. Nowadays the grooves tend to be omitted. The result of this oversight is that the torque required to shear the pin rises as the cutting edges of the propeller bushing and shaft become blunted. Eventually the gears will strip instead.

In larger and more modern engines, a rubber bushing transmits the torque of the drive shaft to the propeller's hub. Under a damaging load the friction of the bushing in the hub is overcome and the rotating propeller slips on the shaft preventing overloading of the engine's components.[8] After such an event the rubber bushing itself may be damaged. If so, it may continue to transmit reduced power at low revolutions but may provide no power, due to reduced friction, at high revolutions. Also the rubber bushing may perish over time leading to its failure under loads below its designed failure load.

Whether a rubber bushing can be replaced or repaired depends upon the propeller; some cannot. Some can but need special equipment to insert the oversized bushing for an interference fit. Others can be replaced easily.

The "special equipment" usually consists of a tapered funnel, some kind of press and rubber lubricant (soap). Often the bushing can be drawn into place with nothing more complex than a couple of nuts, washers and "allscrew" (threaded bar). If one does not have access to a lathe an improvised funnel can be made from steel tube and car body filler! (as the filler is only subject to compressive forces it is able to do a good job) A more serious problem with this type of propeller is a "frozen-on" spline bushing which makes propeller removal impossible. In such cases the propeller has to be heated in order to deliberately destroy the rubber insert. Once the propeller proper is removed, the splined tube can be cut away with a grinder. A new spline bushing is of course required. To prevent the problem recurring the splines can be coated with anti-seize anti-corrosion compound.

In some modern propellers, a hard polymer insert called a drive sleeve replaces the rubber bushing. The splined or other non-circular cross section of the sleeve inserted between the shaft and propeller hub transmits the engine torque to the propeller, rather than friction. The polymer is weaker than the components of the propeller and engine so it fails before they do when the propeller is overloaded.[9] This fails completely under excessive load but can easily be replaced.

See also

Propeller characteristics

Propeller phenomena

Propeller variations

- Azimuth thruster

- Helix

- Impeller

- Jet engine

- Kitchen rudder

- Ducted propeller

- Paddle steamer

- Pleuger rudder

- Propulsor

- Voith-Schneider

- Cleaver

- Bow/Stern thruster

- Folding propeller

- Modular propeller

Materials and Manufacture

Notes

- ^ Mario Theriault, Great Maritime Inventions Goose Lane Publishing (2001) p. 58-59

- ^ "Patch's Propeller", Scientific America, Vol. 4, No. 5 (October 10, 1848) p. 33, featured in The Archimedes Screw website retrieved 31 January 2010

- ^ "History and Design of Propellers: Part 1". the boatbuilding.community. 2004-02-07. http://www.boatbuilding.com/article.php/designofpropellers1. Retrieved 2007-09-03. "Francis Petit Smith accidentally discovered the advantages of a "shortened" Archimedean screw. Originally, his wooden propeller design had two complete turns (what we might call "double-pitch"). Nevertheless, following an accident in a canal, his boat immediately gained speed after half of his blade broke away."

- ^ Ash, Robert L; Britcher, Colin P; Hyde, Kenneth W. "prop-Wrights: How two brothers from Dayton added a new twist to airplane propulsion". Mechanical Engineering - 100 years of flight. http://www.memagazine.org/supparch/flight03/propwr/propwr.html. Retrieved 2007-09-03.

- ^ Illustrations of skewback propellers

- ^ http://www.engineeringnews.co.za/article/a-new-start-for-marine-propellers-2005-03-18

- ^ Getchell, David, The Outboard Boater's Handbook, http://books.google.co.uk/books?id=YpMTd7-Mb3sC

- ^ Admiralty Manual of Seamanship, http://books.google.co.uk/books?id=jUdZlpHWShkC

- ^ US 5484264, Karls, Michael & Daniel Lindgren, "Torsionally twisting propeller drive sleeve and adapter", published March 8, 1994, issued January 16, 1996

External links

- Titanic's Propellers

- "What Your Should Know About Propellers For Our Fighting Planes", November 1943, Popular Science extremely detailed article with numerous drawings and cutaway illustrations

- Josef Ressel

- Archimedes Screw History: The story of marine propulsion]

![\mbox{d}L = \frac {1}{2}\rho V_1^2 C_L dA = \frac {1}{2}\rho C_L[V_a^2(1%2Ba)^2%2B4\pi^2r^2(1-a')^2]b\mbox{d}r](/2012-wikipedia_en_all_nopic_01_2012/I/7253f9578b848a4ab4d6f175a709b04b.png)

![\begin{align}V_1^2 &= V_a^2(1%2Ba)^2%2B4\pi^2r^2(1-a')^2\\

\mbox{d}D &= \frac{1}{2}\rho V_1^2C_D\mbox{d}A = \frac{1}{2}\rho C_D[V_a^2(1%2Ba)^2%2B4\pi^2r^2(1-a')^2]b\mbox{d}r\end{align}](/2012-wikipedia_en_all_nopic_01_2012/I/d693b0ca51e53b61e1b44e913d07db07.png)

![T = \rho V^2 D^2 [ f_1(\frac {ND}{V_a}), f_2(\frac {v}{V_a D}), f_3(\frac {gD}{V_a^2}) ]](/2012-wikipedia_en_all_nopic_01_2012/I/87dbab8cde47f0ea6729b6c491ee1bcb.png)